Thermal Management

Power dissipation and thermal management are major considerations in advanced chip design, posing several challenges that critically impact performance and functionality. Key issues include: Increased heat generation, performance degradation, limited thermal budget, reduced efficiency, plus packaging and design complexities. iNPACK are leaders in the continuous development of new techniques and innovative approaches that provide proven power dissipation solutions in advanced package design.

Critical design aspects to be considered

Major heat-dissipating components

Board size and thickness

Materials, layout, & component placement

Mounting peripherals

Application conditions & environment

Amount of heat to be dissipated

Cooling methods, (fans, heat sinks, etc.)

Our solutions

Cu coins (I-coin, T-coin, custom-coin)

Heat sinks (soldered, conductive adhesive, non conductive)

Thermal vias (Cu-filled, epoxy filled)

Cu thickness

Integrated active cooling designs

Specialized assembly solutions

Frequently Asked Questions

What are the primary challenges with thermal management while designing a PCB

Engineers face several critical thermal challenges. As chip density and power increase, there’s increased heat generation in a smaller area, leading to hotspots. This excess heat can cause performance degradation (like reduced system speed), and lower power efficiency can shorten component lifespan. The overall design is constrained by a limited thermal budget, and managing this heat introduces significant packaging and PCB layout complexities, requiring careful consideration of materials and component placement to ensure reliability.

What initial design aspects are critical for effective PCB thermal management?

Effective PCB thermal management begins at the conceptual design stage. Engineers must identify major heat-dissipating components and their specific cooling requirements. Critical decisions include the board size, layer stack-up, and material selection (e.g., standard FR-4 vs. high-Tg or ceramic substrates). The layout and placement of components are paramount—spreading out hot components and keeping them away from sensitive areas is crucial. Finally, the intended application conditions and environment will dictate the necessary cooling methods, from passive heat sinks to active solutions.

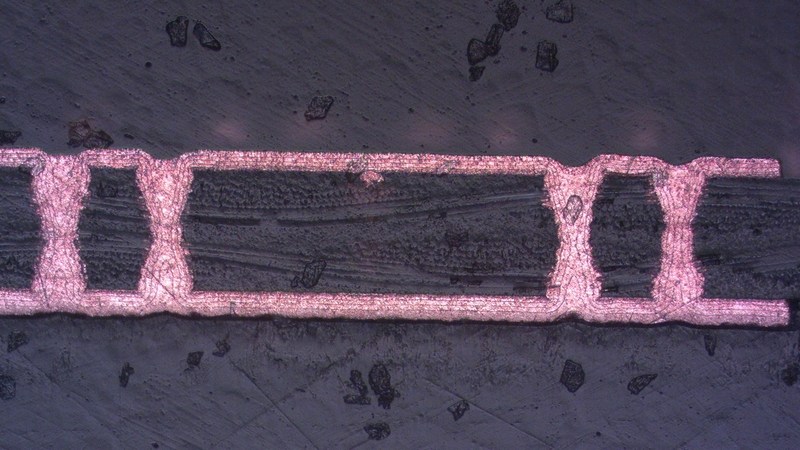

What are thermal vias, and how do they contribute to PCB thermal management?

Thermal vias are holes drilled through the PCB, typically under a heat-generating component, that are plated with copper and often filled with conductive epoxy. They act as highly efficient vertical pathways to transfer heat from the component on the top layer down to the internal or bottom copper planes. These planes act as large heat spreaders, dissipating the thermal energy over a much wider area and significantly reducing the temperature of the component.

What are "Cu coins" and when are they used?

A copper coin (such as an I-coin or T-coin) is a solid piece of copper that is embedded, or “coined,” directly into a cutout in the PCB during fabrication. This creates a direct, low-resistance thermal path from a critical component (like a high-power processor or FET) to a heat sink on the opposite side of the board. This technique is superior to thermal vias for managing very high, concentrated heat loads because it offers a continuous, solid metal path for maximum thermal conductivity, bypassing the PCB substrate entirely.

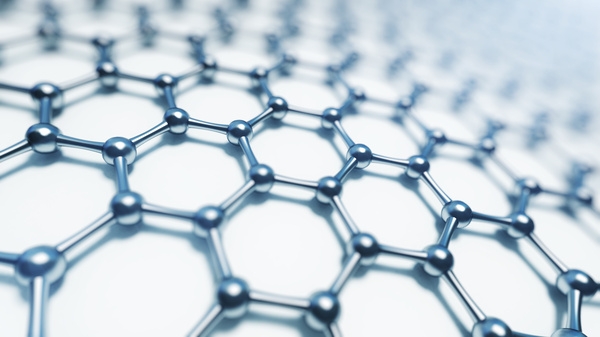

How does the choice of PCB substrate material impact thermal management?

The substrate material is fundamental to thermal performance. Standard FR-4 has relatively low thermal conductivity (around 0.3 W/m·K). For high-power applications, engineers may select advanced materials like polyimide (for high temperatures) or ceramic-based substrates (like aluminum nitride, with conductivity up to 170 W/m·K) for superior heat dissipation. Another option is a Metal-Core PCB (MCPCB), which uses a metal base (typically aluminum) to act as an integrated heat sink for the entire board, ideal for applications like LED lighting and power electronics.

What are the main differences between active and passive cooling solutions for PCBs?

Passive cooling relies on natural heat transfer principles (conduction, convection, radiation) without consuming extra power. Examples include heat sinks, increasing copper plane thickness, thermal vias, and high-conductivity materials. Active cooling involves powered components to forcibly remove heat. This includes solutions like fans, blowers for forced air convection, and more advanced systems like liquid cooling (using cold plates or heat pipes) and thermoelectric coolers (Peltier devices), which are necessary when passive methods are insufficient to keep components within their safe operating temperatures.

How can component placement and layout be optimized for better thermal performance?

Strategic component placement is a key, low-cost thermal management technique. High-power components should be distributed across the board to avoid creating localized hotspots. Whenever possible, they should be placed toward the center to allow heat to spread in all directions or near the board edges if heat sinks are mounted there. Sensitive components, like analog circuits or sensors, should be physically isolated from major heat sources. Ensuring adequate spacing between all components prevents heat from becoming trapped and allows for better airflow.

Beyond traditional heat sinks, what are some of the specialized assembly and integrated solutions for thermal management?

Advanced thermal management involves more than just attaching a heat sink. Specialized assembly solutions include using high-conductivity thermal interface materials (TIMs) like thermal grease or pads to ensure a void-free connection between a component and its heat sink. Heat sinks themselves can be attached with conductive adhesives for a permanent, thermally efficient bond. Furthermore, integrated active cooling designs represent a more advanced approach where cooling channels for liquid or air are designed directly into the package or module itself, offering a highly efficient and compact solution for the most demanding applications.

iNPACK Relevant content

See All Articles

articles

X-VIA Technology: Critical for HDI Packages

articles

Why Introduce Graphene into Advanced PCBs?

articles

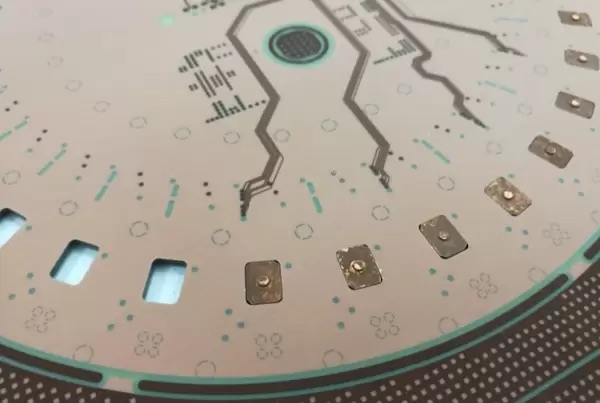

PCB Thermal Management Solutions

PCBs are the first heat management platform that electrical components meet. How you choose to handle the heat very much depends on the power dissipated from constituent components, line losses, board design, circuit editing, and mechanical structure. There are also thermal effects that arise from interconnect options on the board level, vias, transmission lines and assembly pad design.