Superior heat dissipation, organic substrate and advanced packaging solutions

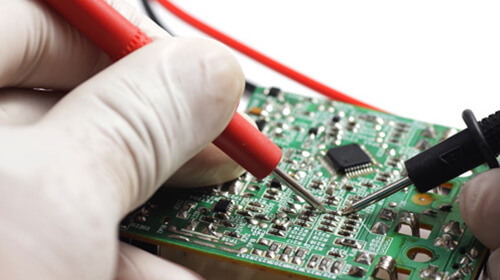

The ever-growing demand for energy-consuming appliances in our daily lives, creates the need for renewable energy and high-power applications solutions. Just a few examples of that are LED lighting panels and energy-saving GPS technology devices; all of which rely on quality, high reliability, high performance PCBs to manage their performance in various environmental conditions, while using alternative energy resources, such as wind, solar or hydroelectric energy.

We, at PCB Technologies, offer our customers an All-in-One solution to meet these demands.

The greater benefit of this approach materializes if we can get involved in your project from the early stages of your PCB design, through its fabrication, and testing; especially when it comes to organic substrate and advanced packaging solutions, allowing their miniaturization to tiny form factors. Our decade-long experience in thermal management enabling heat dissipation of these high-power components can come in handy when designing your PCB, taking into account, not only the technological aspect but also cost-effectiveness and supply chain constraints.