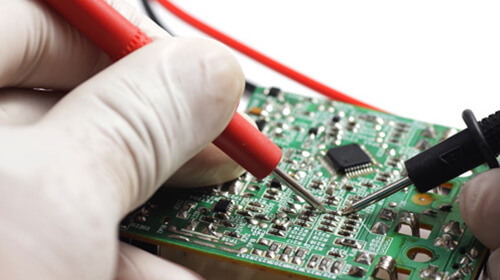

High reliability, high-speed & high-density interconnect PCBs

We have grown accustomed to semiconductor supply chain delays ever since the COVID19 era began, and their effect on the lives of people all over the world is accelerating. The ever-growing demand for High-Density Interconnects, the main building block of electronic miniaturization technology, sets yet another challenge for PCB designers and manufacturers. These PCBs are expected to have extended functionality as well as decreased weight and energy consumption and deliver highly reliable, high-speed volume data transmissions meeting the market derivative of 5G technologies. All these are basic requirements in various applications they are designated for, such as automotive, aerospace, and medical, among others.

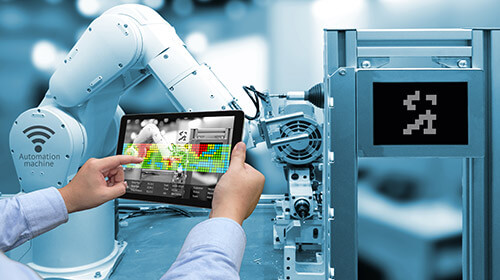

Semiconductor machine manufacturers, operating under tremendous stress to keep up with the ongoing global market demand for PCBs require not only high-speed operating machines but also highly accurate and reliable ones. PCB Technologies offers high reliability, high speed and high-density interconnect PCBs for the most advanced semiconductor manufacturers utilizing its vast and decade-long experience in raw materials, design, and fabrication. Contact Us today for more information.