LET'S TALK

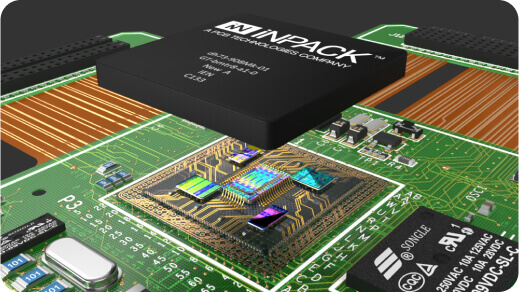

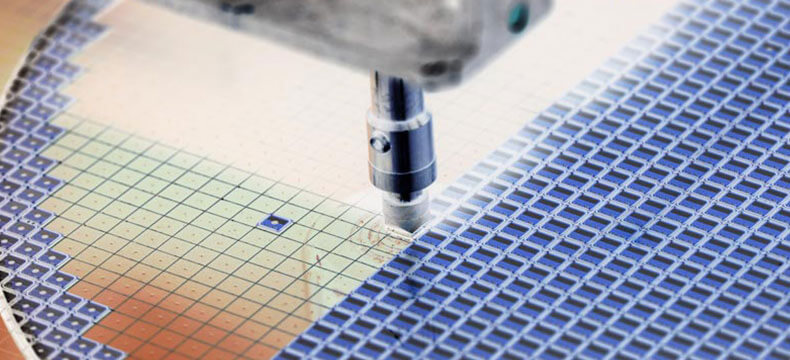

Miniaturization (iNPACK) - Organic Substrates & Advanced IC Packaging Solutions

Explore Solutions

Industry 4.0 / 5.0

Strategic Capabilities for Aerospace & Aviation PCBs

HDI & Miniaturization Technologies

High-Reliability, High-Quality PCBs - Prototype to Low/Mid Production Volumes

HDI, Rigid/Rigid-Flex, RF Boards, Heat Management Solutions & More

Self-driving Technology Rides on High Reliability, High-Performance Execution Enabled by PCBs

Advanced Communications Systems Depend on High-Reliability PCBs

High-Power PCBs for Energy Industries

Our highly experienced engineering team is at your service – from design to fabrication for an All-in-One solution

Our sales team will be happy to provide you with a quote. Simply send us an email detailing your requirements and we’ll reply ASAP

Frequently Asked Questions

What services does PCB Technologies offer?

PCB Technologies provides comprehensive solutions encompassing PCB fabrication, PCB assembly (PCBA), and advanced miniaturization through our iNPACK platform. Our services include supply chain management, assembly, testing, inspection, rework, and New Product Introduction (NPI).

Which industries does PCB Technologies serve?

We cater to a diverse range of industries, including aerospace, defense, automotive, medical electronics, communications, semiconductor, consumer electronics, and energy sectors. Our solutions are tailored to meet the specific needs of each industry, ensuring high reliability and performance.

What is iNPACK, and how does it benefit my designs?

iNPACK is our advanced IC packaging and miniaturization solution that integrates organic substrates and System-in-Package (SiP) technologies. It enables size reduction, enhanced thermal conductivity, and improved signal integrity, making it ideal for compact and high-performance electronic devices.

Can you handle both prototype and mass production?

Yes, we support projects from prototype to low and mid-volume production. Our flexible manufacturing capabilities ensure that we can scale production to meet your specific requirements, maintaining high quality and efficiency throughout.

What quality standards does PCB Technologies adhere to?

We are committed to delivering products that meet the highest industry standards. Our certifications include ISO 9001, ISO 14001, ISO 13485, and AS 9100. Our Quality Control staff are trained and certified in IPC Class 2 and 3, ensuring consistent quality and compliance across all our manufacturing processes.

Do you offer design support services?

Absolutely. Our experienced engineering team provides Design for Manufacturing (DfM) and Design for Assembly (DfA) services and also design support in the IC packaging segment, offering valuable insights to optimize your designs for manufacturability and cost-effectiveness.

What is your approach to thermal management in PCBs?

We employ advanced thermal management solutions, including embedded coins, via farms, heat sink integration, thick copper, controlled CTE materials, and optimized stack-ups, to ensure effective heat dissipation in high-power applications.

How do you ensure the timely delivery of projects?

Our global manufacturing network, coupled with efficient logistics and project management, allows us to meet tight deadlines and deliver products on time, even for complex and custom designs.

Can you assist with New Product Introduction (NPI)?

Yes, we offer comprehensive NPI services, guiding your product from concept through prototyping to full-scale production. Our team works closely with you to ensure a smooth transition and successful market entry.

articles

Semiconductor breakthroughs allow compact, energy-efficient medical devices for continuous monitoring and treatment. Medical device miniaturization is reshaping healthcare with smaller, smarter electronics and real-time sensing. Explore the challenges and manufacturing solutions behind ultra-small medical electronics and implantable devices. Explore medical miniaturization trends.

events

Meet with us @ IMAPS Device Packaging 2026

Join us at IMAPS DPC 2026

Phoenix, Arizona March 3-4, Booth #506

events

Join us at DesignCon 2026

Santa Clara, USA February 25-26, Booth #305

We will contact you shortly