PCB Thermal Management Solutions

Yaniv Maydar

|12th February ,2024

Introduction

As electronic devices pack more power into smaller spaces, heat generation can prove to be a major setback. This is where PCB thermal management solutions become critical. However, there’s no single all-around heat dissipation remedy. Rather it’s often a combination of many different techniques or methods combined that provide an optimal thermal management solution; to ensure component reliability, performance, and longevity.

How you choose to handle the heat very much depends on the power dissipated from constituent components, line losses, board design, circuit editing, and mechanical structure. There are also thermal effects that arise from interconnect options on the board level, vias, transmission lines and assembly pad design.

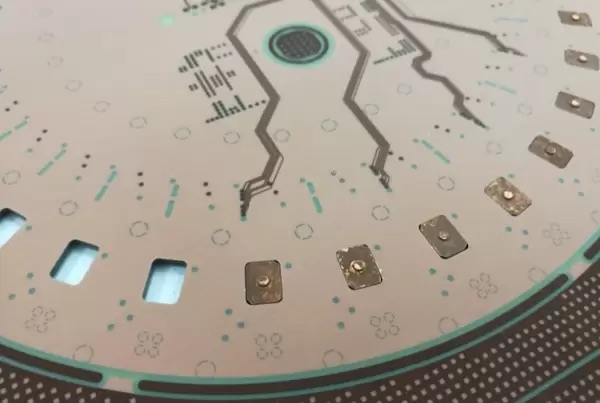

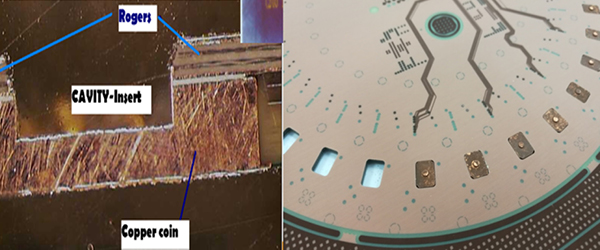

Therefore, one of the main challenges facing PCB designers is to design boards that work within required environmental specifications and according to the thermal effects of the components in the design. Some PCB designs may require the use of heat management techniques such as heat sinks, conductive and non-conductive connections, coin inserts embedded in the board, Cu-filled vias, via farms and integrated active solutions such as fans.

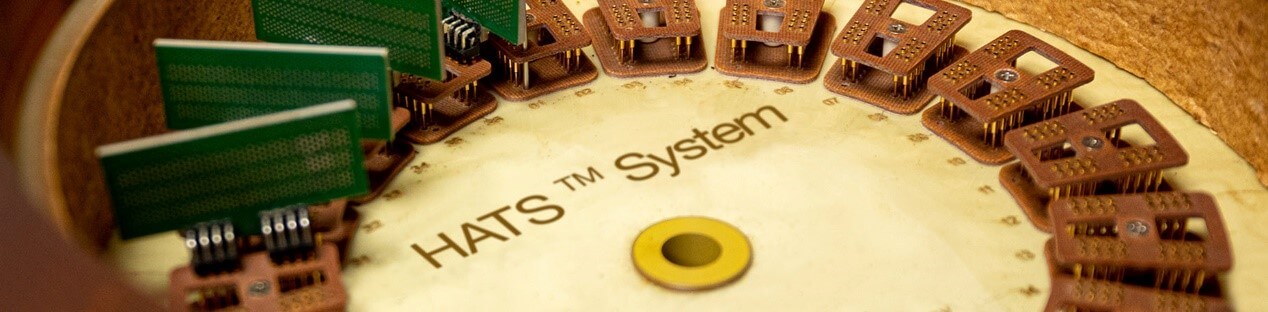

Through our long experience working with defense industries and in the high-power sector, PCB Technologies has become a leading solutions provider in the field of PCB heat management.

Our approach is to partner with designers from the initial design stages; keeping a critical eye on design aspects that will provide superior thermal solutions for PCBs such as:

- Major heat-dissipating components

- Board size and thickness

- Materials, layout, & component placement

- Mounting peripherals

- Application conditions & environment

- Amount of heat dissipated

- Cooling methods, (fans, heat sinks, etc.)

By taking into consideration the factors listed above and more, PCB Technologies assists our customers to integrate best-practice thermal solutions into their board designs from the very start. Thermal management solutions we provide include:

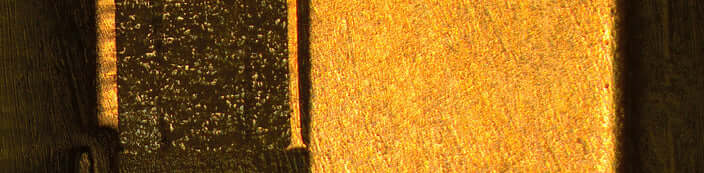

- Cu coins (I-coin, T-coin, custom-coin)

- Heat sinks (soldered, deductive adhesive, non-conductive)

- Thermal vias (Cu-filled, epoxy filled)

- Cu thickness

- Integrated active cooling designs

- Specialized assembly solutions

Important to note: Designing with thermal management in mind means starting with a thermal simulation, carefully reviewing thermal solutions, and assessing how the manufacturing process will affect performance and price. Only then can you determine optimal board requirements.