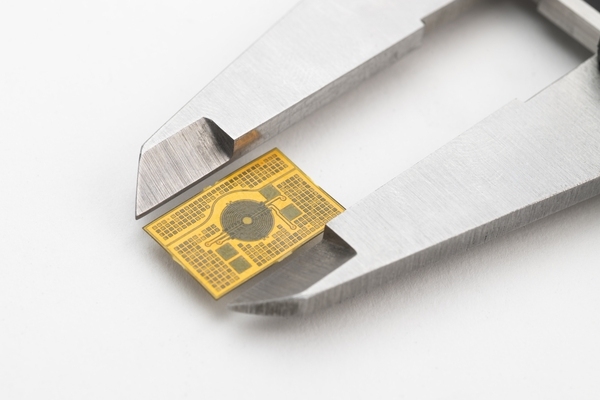

Organic Substrate

Features

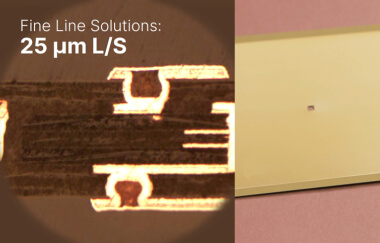

1/1mil L/S

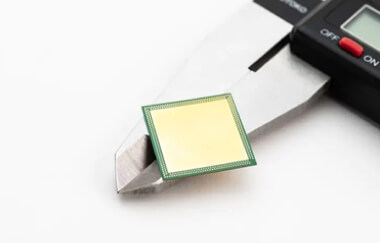

Cu pillars

Low CTE

High thermal conductivity

50-80 um via diameter

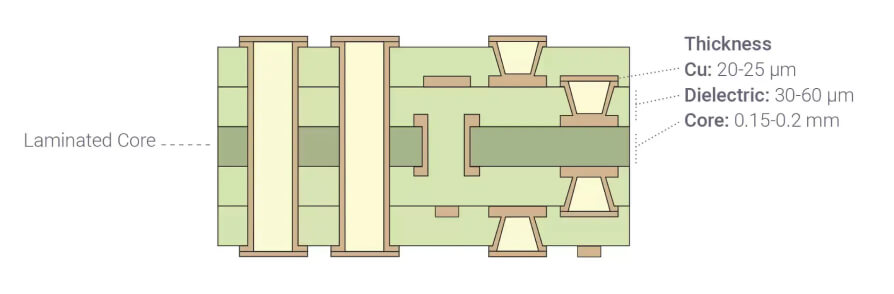

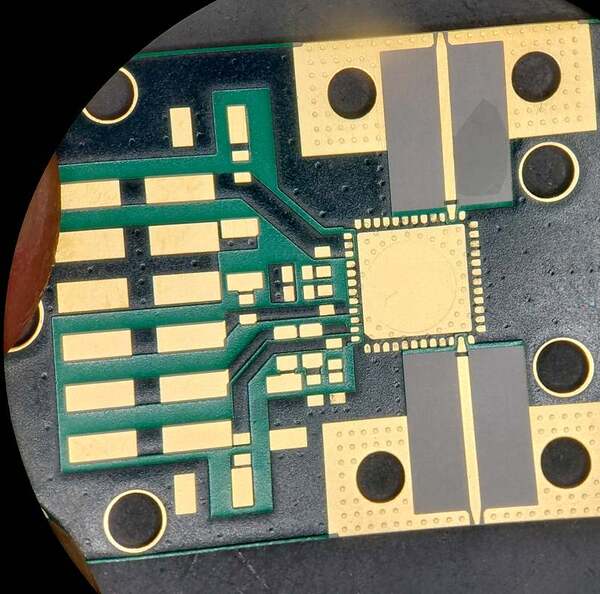

Fan-in /Fan-out through inserts

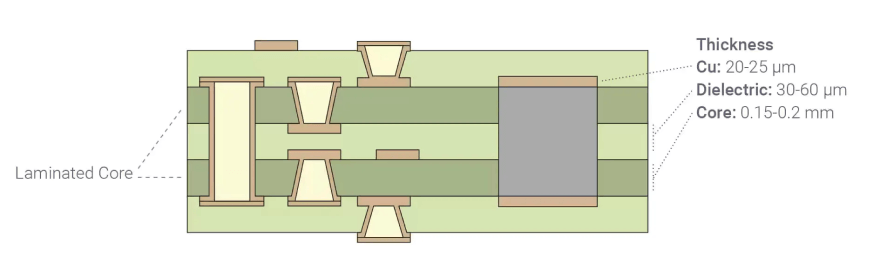

Interposer/connector substrates

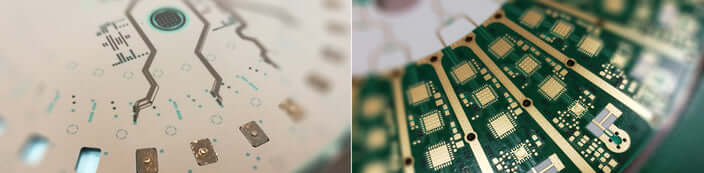

Types

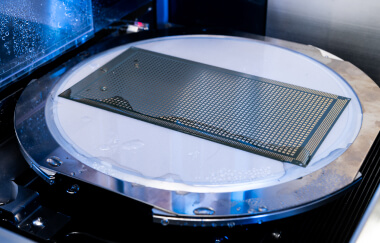

Rigid or Flex substrates

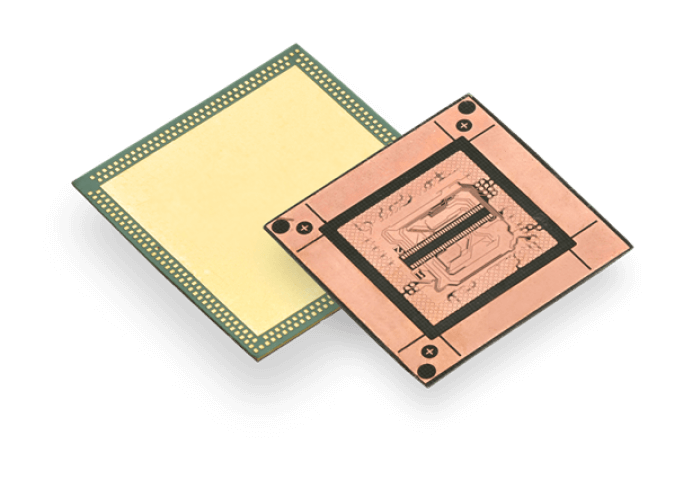

Organic substrates

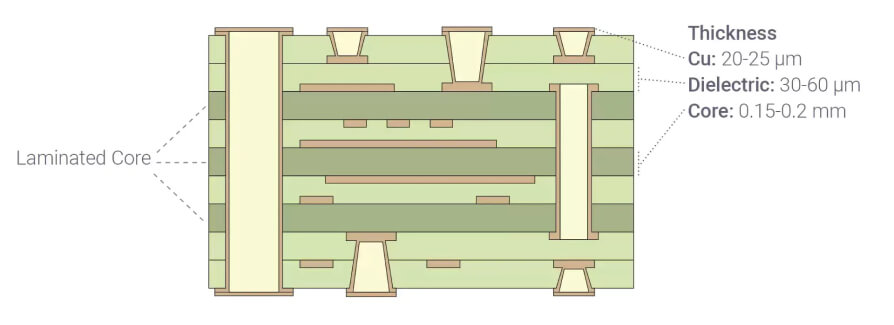

Laminate substrates

Build-up substrates

Applications

Medical

Automotive

Aerospace

Power

Communications: high-speed digital

Optical

Frequently Asked Questions

What is the minimum line and space (L/S) resolution achievable with iNPACK's substrates?

iNPACK’s substrates support a minimum line and space resolution of 1/1 mil.

Does iNPACK offer solutions for managing thermal expansion in demanding applications?

Yes, they offer substrates with a low coefficient of thermal expansion (CTE) to address thermal management challenges.

What is the typical via diameter range for iNPACK's substrates?

The typical via diameter ranges from 50 to 80 micrometers (μm).

How does iNPACK accommodate high-density interconnects?

We support high-density interconnects through features like copper (Cu) pillars and the ability to design for fan-in/fan-out through inserts.

For which specific high-speed communication applications are iNPACK substrates suitable?

Our substrates are suitable for high-speed digital, RF, and optical applications.

What dielectric materials are typically used in organic substrates to support signal integrity at high frequencies?

Low-loss dielectric materials such as modified epoxy resins or BT (Bismaleimide Triazine) are commonly used to reduce signal attenuation and maintain integrity in high-speed transmission environments.

How do organic substrates contribute to electrical insulation in high-density packaging applications?

Multilayer organic substrates often incorporate high dielectric strength materials and optimized layer stacking to minimize crosstalk and ensure reliable insulation between adjacent signal traces.

What surface finishes are compatible with organic substrates for reliable soldering and wire bonding?

Standard surface finishes include ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), OSP (Organic Solderability Preservative), and immersion silver or gold, all of which enhance solderability and wire bonding reliability.

How is moisture sensitivity managed in organic substrate-based assemblies, and what testing protocols are used to ensure reliability?

Moisture-resistant resin systems are selected, and assemblies typically undergo JEDEC-level Moisture Sensitivity Level (MSL) testing to ensure performance stability under humid or thermally stressful conditions.

What design techniques are used in organic substrates to enable RF shielding in mixed-signal or wireless modules?

Our techniques include integrating dedicated ground planes, the use of stitched vias for shielding, and the strategic placement of shielding layers to suppress EMI and maintain RF performance integrity.

iNPACK Relevant content

See All Articles

articles

SLP – Substrate-Like PCB Technology

Eye-opening interview with PCB Technologies’ CTO Yaad Eliya about SLP Technology; exploring its huge growth potential and far-reaching impact on the design, fabrication and manufacturing processes of today’s hottest new products, applications, and near-future innovations.

articles

Focusing on Substrate PCB Manufacturing

articles