Exploring the Technological Building Blocks

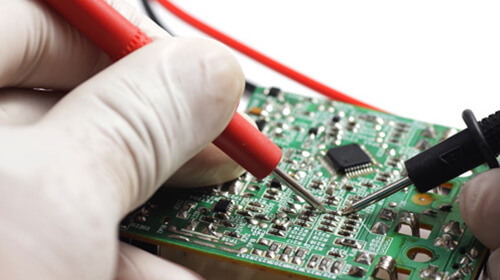

- Integrated Circuits (ICs):

Commonly called chips, ICs are the fundamental component in the development of many advanced aerospace-related devices, instruments and equipment. Their uses encompass an almost an endless list of strategic operations, including communications networks, navigational systems, flight controls, threat detection, fueling, electro-optic (EO/IR), weather radar, guidance systems and much more.

- Power Management ICs (PMICs):

These miniaturized ICs perform vital optimization of critical systems on aircraft and enhance energy distribution; extending battery life and improving system reliability. They can enable innovative avionics features like glass cockpits; providing pilots with real-time data designed to increase situational awareness and simplify cockpit management.

- Micro-electromechanical Systems (MEMS):

MEMS are tiny machines that combine electronic and mechanical components, typically ranging from 1-100 microns in size. They’re designed to boost device performance and reliability; resulting in higher accuracy, faster response times, lower power consumption and cost savings. Typical MEMS-powered devices in Aerospace include accelerometers, gyroscopes, pressure sensors, temperature sensors and microvalves for navigation, control systems and fuel management.

- Radio Frequency (RF) Components:

RF components, such as antennas, transceivers, and frequency synthesizers, offer streamlined communications and navigational functionality in the Aerospace arena. More compact antennas can boost communication capabilities, while transceivers ensure reliable data exchange. Frequency synthesizers enhance navigation systems like a GPS, to allow more accurate tracking and positioning. Refer also to: Antenna-in-Package.

Key Benefits of Miniaturization in Aerospace Applications

- Cost Reduction: Miniaturization reduces payload mass and volume, enabling more ambitious space exploration missions at reduced launch costs, and faster more agile and accurate high-performance aircraft.

- Resource Optimization: Miniaturized systems allow the integration of more mission-critical components packed into smaller spaces, such as sensors, wireless communication devices, control units and power generators. This increases payload efficiency, reduces power losses and enhances thermal management.

- Reliability & Flexibility: Integrating multiple microsystems into a silicon wafer and redundancy by design has increased reliability and flexibility. Smaller, more reliable systems can also reduce operating risks associated with space missions.

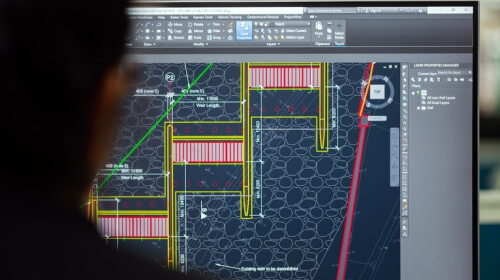

PCB Manufacturing at its Best

PCB Technologies’ High-Density Interconnect (HDI) boards or PCBA with BGA connectors, are fundamental to our offerings, along with Rigid-Flex PCBs and Radio Frequency (RF) boards. We also excel in advanced heat management solutions, critical for high-power electronics typical in Aerospace & Aviation applications. We utilize specialized thermal interface materials and design features to ensure sensitive components remain within safe parameters.

PCBs Best Suited for Applications in Aerospace & Aviation

- HDI PCBs (High-Density Interconnect): Ideal for aerospace and aviation due to their ability to pack more functionality into a smaller, lighter footprint. In an industry where size and weight are critical for fuel efficiency and performance, the use of micro-vias and fine lines allows for complex, multi-layered designs.

- Avionics Systems: Used in flight control computers, navigation units and cockpit displays to reduce space and weight while maintaining high reliability.

- Satellite Systems: Employed in communication transceivers and data acquisition units to handle complex signals and save precious mass.

- Radar Systems: Found in radar transmitters and receivers where high-density routing is needed for high-frequency signal integrity.

- UAVs (Drones): Essential for the compact and powerful electronic systems required in unmanned aerial vehicles.

- Rigid-Flex PCBs: Combining the durability of a rigid board with the flexibility of a flex circuit, rigid-flex PCBs are perfect for applications that require a robust design that can fit into tight or irregularly shaped spaces. They eliminate the need for bulky connectors and wires, which reduces weight and potential failure points.

- Satellite & Spacecraft Systems: Used for wiring within satellites and antenna control systems, where they must withstand extreme vibrations and conform to the structure.

- Aircraft Engine Control (FADEC): Integrated into engine monitoring sensors and control systems (Full Authority Digital Engine Control) due to their resistance to vibration and thermal cycling.

- Cockpit & Instrument Panels: Enables the complex, 3D packaging of electronics behind displays and control panels, navigating in confined spaces.

- RF Boards (Radio Frequency): RF boards are specially designed to handle high-frequency signals with minimal loss and interference. They use specialized materials like PTFE or ceramic-based laminates to maintain signal integrity, which is crucial for communication and radar applications.

- Radar & Communication Systems: The backbone of airborne and ground-based radar, satellite communications and high-frequency data links.

- GPS Systems: Essential for navigation systems in aircraft, processing high-frequency signals from satellites with precision.

- Air Traffic Control (ATC): Found in ground-based and airborne ATC systems for reliable communication and surveillance.

- Heat Management: Electronics in aerospace and aviation generate significant heat and must operate in environments with extreme temperature variations. Effective thermal management is critical to prevent component failure and ensure the longevity of mission-critical systems.

- Avionics & Flight Control: Systems in the cockpit and throughout the aircraft rely heavily on varied thermal management solutions and unique combinations of advanced techniques to dissipate heat from high-power processors and power units.

- High-Powered Radar: Advanced aerial radar systems with high power densities require sophisticated cooling, often employing specialized cooling technologies and complex materials to prevent overheating.

- Spacecraft & Satellite Electronics: Satellites in the vacuum of space face extreme temperatures. Highly advanced thermal management systems are a necessity to keep sensitive electronics within operational temperature range.

AS9100 & NADCAP Certified

We comply with AS9100, international standard for an aerospace quality management system that applies to the entire organization, focusing on processes, products and services to ensure safety and reliability. NADCAP (National Aerospace and Defense Contractors Accreditation Program) is a specialized accreditation focused on specific “special processes” critical to aerospace manufacturing, such as heat treating or welding, that require technical expertise and are subject to rigorous, industry-specific audits.

Critical Vibration Testing

PCB Technologies has recently upgraded to a new highly-advanced Electrodynamic Shaker system, augmenting our inhouse final testing capabilities. It’s a definite must-have for Aerospace & Aviation industry clients who require versatile test protocols that deliver extreme precision, while simulating a wide range of real-world flight and launch conditions to ensure safety, reliability and durability for both aircraft and spacecraft components.

Key Electrodynamic Shaker Tests for Aerospace & Aviation

- Launch Simulation: Testing satellite and spacecraft components to ensure they can withstand the extreme vibration and shock environments of a rocket launch.

- Aircraft Component Testing: Evaluating the durability of avionics, flight control systems, engine parts and landing gear under constant vibrations of flight.

- Modal Analysis: Exciting the structure to measure natural frequencies and mode shapes; to validate mathematical models and optimize designs against destructive resonance.

- Environmental Stress Screening (ESS): Combines vibration with other environmental stressors, such as temperature and humidity, to expose weaknesses in electronic components and solder joints.

End-of-Life (EOL) OSAT Solutions

PCB Technologies is a leading provider of custom OSAT solutions including EOL and near-EOL products. We offer advanced, high-reliability packaging and substrate solutions with the flexibility of no minimum volume requirements.

If you’ve been left stranded by an OSAT partner or need to revive an internally discontinued product line, our team can deliver an immediate, cost-effective solution to keep your products in continuous operation.

What’s Next?

Any and all technological breakthroughs in electronic systems require the cutting-edge know-how of design engineers coupled with advanced PCB manufacturing and high-level miniaturization fabrication and IC packaging capabilities, to enable today’s most sophisticated Aviation & Aerospace applications; while building future possibilities we can only dream about.

iNPACK (A PCB Technologies Division)

When you think miniaturization, think iNPACK. Experts in organic substrates and enhanced micro-electronics packaging technologies. iNPACK capabilities enable us to deliver complete and comprehensive substrate panel-level manufacturing and engineering support to our customers across the board, in fact they depend on it. (LINK to Webpage)