Broad Vision

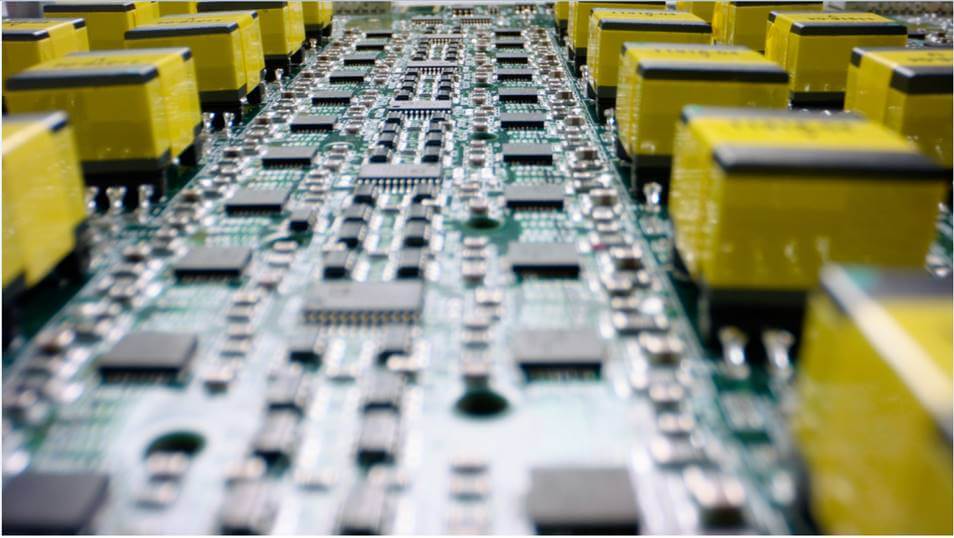

PCB Technologies and its PCB Assembly division (AMS Electronics) provide high-mix high-technology electronic assembly solutions. Our processes and procedures are designed to provide maximum flexibility and quick response to your changing needs.

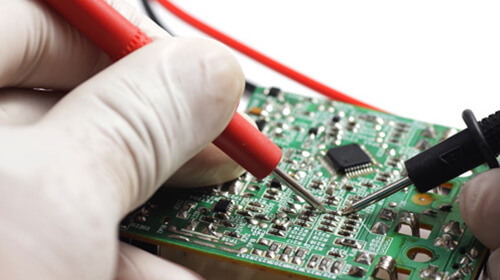

With a highly experienced technological team we can support the most complex assembly technologies, including: 01005 placement, POP Placements, multi layers boards, complex BGA’s/QFN and more.

We have long years of experience in industrial and consumer electronics products manufacturing to include industrial, and medical products, audio-visual appliances, wireless communications equipment and devices, and computer boards, to name a few.

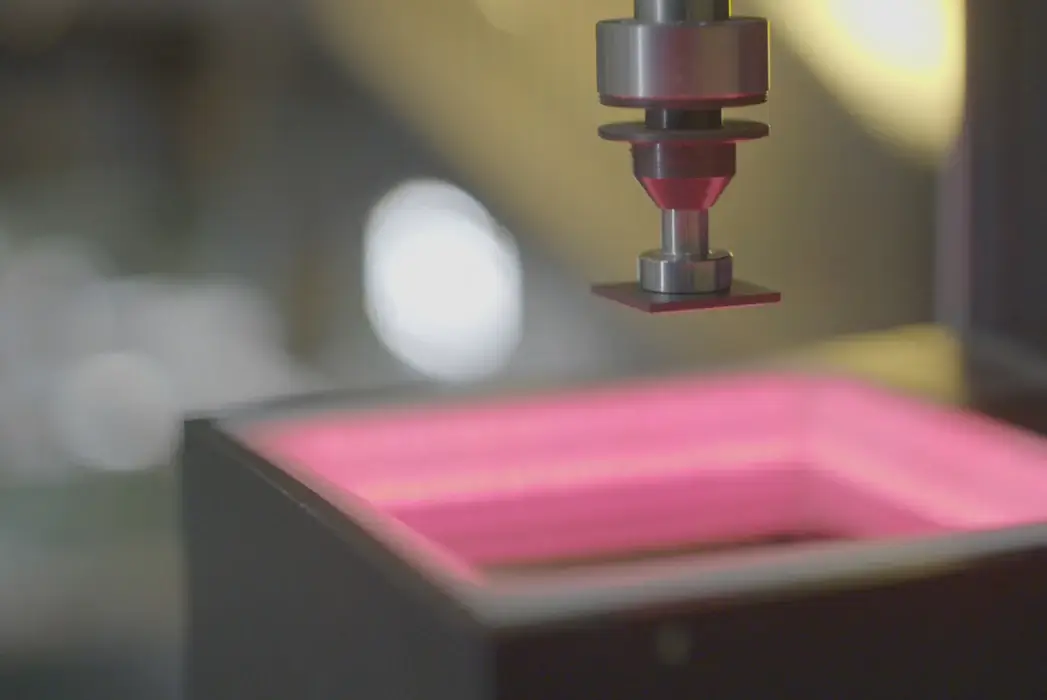

Backed with state-of-the-art, fully computerized equipment and a highly advanced Information System we take pride in our paperless production floor. Our PCB manufacturing capacity can handle small, medium or large volume production levels.