Miniaturization: The New Frontier in Aerospace

Tal Levy

|30th January ,2024

Aerospace and Space Robotics applications are presently infused with miniaturized technologies almost unheard of a decade ago. AI-powered visual and sensory control systems, futuristic wearable devices, multi-operational UAVs, and near science fiction-like micro-satellites, to name a few.

The remarkable building blocks driving these breakthrough developments are complex miniaturized components and micro/nanotechnologies, such as specialized Integrated Circuits (ICs), Micro-electromechanical Systems (MEMS), and Radio Frequency (RF) Sub-systems.

- Integrated Circuits (ICs):

Commonly called chips, ICs are the fundamental component in the development of many advanced aerospace-related devices, instruments and equipment. Their uses encompass an almost an endless list of strategic operations, including communications networks, navigational systems, flight controls, threat detection, fueling, electro-optic (EO/IR), weather radar, missile systems and much more. - Power Management ICs (PMICs):

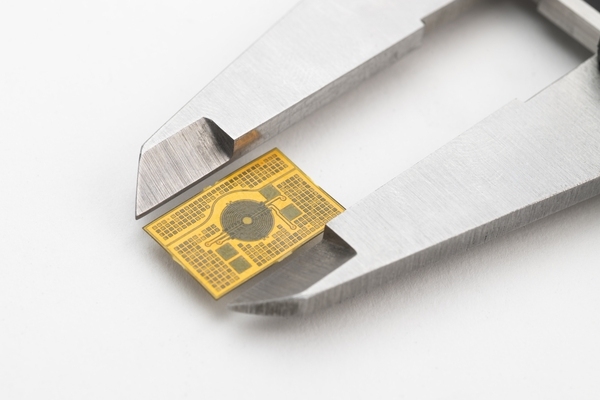

These miniaturized ICs perform vital optimization of critical systems on aircraft and enhance energy distribution; extending battery life and improving system reliability. They can enable innovative avionics features like glass cockpits; providing pilots with real-time data designed to increase situational awareness and simplify cockpit management. - Micro-electromechanical Systems (MEMS):

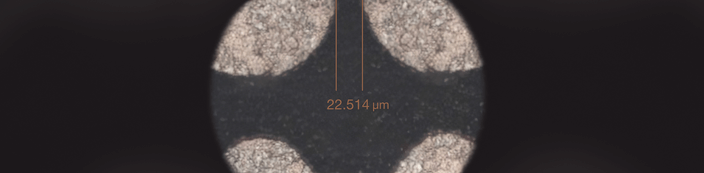

MEMS are tiny machines that combine electronic and mechanical components, typically ranging from 1-100 microns in size. They’re designed to boost device performance and reliability; resulting in higher accuracy, faster response times, lower power consumption and cost savings. Typical MEMS-powered devices in Aerospace include accelerometers, gyroscopes, pressure sensors, temperature sensors and microvalves for navigation, control systems and fuel management. - Radio Frequency (RF) Components:

RF components, such as antennas, transceivers, and frequency synthesizers, offer streamlined communications and navigational functionality in the Aerospace arena. More compact antennas can boost communication capabilities, while transceivers ensure reliable data exchange. Frequency synthesizers enhance navigation systems like a GPS, to allow more accurate tracking and positioning.

(see also: Antenna-in-Package)

Must-have Wearables for Aerospace:

Miniaturized technology has introduced wearable devices and instruments to the aerospace industry that have quickly become indispensable. Some examples include:

- Smart Glasses & Smart Watches: offering immediate information sharing and heightened efficiency during aircraft production, quality control processes, and maintenance procedures.

- Augmented Reality Displays: delivering real-time information for critical cockpit management, heightened situational awareness, and quicker response times in emergency situations.

- Visual Sensors on Gloves: Giving pilots and equipment operators the ability to check out possible malfunctions or perform maintenance in confined spaces or other places where human eyes can’t go.

- Haptic Feedback Suits: A full body covering providing feedback in the form of physical sensations. Designed to equip pilots with enhanced situational awareness, improved communication, and biometric monitoring. In space, haptic actuators up against an astronaut’s skin can transduce sensory data from the external environment through the pressurized suit, allowing astronauts the sensation of feel/touch input right through their spacesuit.

Satellite Systems:

Miniaturization has led to the development of far smaller, more affordable satellites, including CubeSats and nano-satellites. These satellites integrate miniature components for onboard computers, communication systems, and ultra-compact imaging equipment, generating operational improvements in weather forecasting, communications, scientific research, and national defense systems.

Space Robotics:

Micro/Nanotechnologies (MNT):

MNT encompasses a broad range of technologies, including MEMS, nanotechnologies, and miniature robotic technologies; collectively referred to as MNT or microsystems. In the context of space robotics, miniaturization refers to the reduction of component size and mass, while maintaining or even increasing functionality. It also involves reducing the overall size of the robotic system.

Advantages of MNT in Space Robotics:

- Construction of smaller systems; allowing lower launch costs and reduced resource requirements.

- Integrating sensors, wireless communications, control units, and power generation into a smaller package, increasing efficiency, reliability and flexibility.

- Silicon wafer microsystems for cost advantages and improved performance.

- Terrestrial micro-technologies, utilized for point-to-point communication, provide a more cost-effective, sustainable solution.

Applications in Space Robotics:

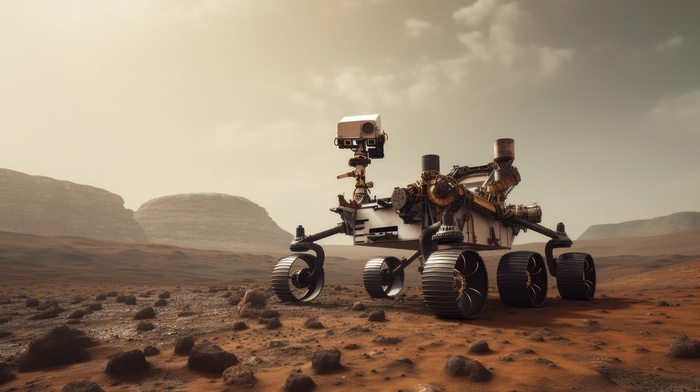

Semi or fully autonomous, teleoperated space robotics systems play a crucial role in servicing space stations, satellite maintenance, scientific research projects and inter-planetary exploration missions. The integration of micro and nanotechnologies in space robotics has opened up a new era for missions beyond Earth’s orbit.

Key Benefits of Miniaturization in Space Robotics:

- Cost Reduction: Miniaturization reduces the payload mass and volume, enabling more ambitious space exploration missions and reduced launch costs. Significant savings when it comes to long space exploration missions, e.g., the Moon, Mars, or Asteroids.

- Resource Optimization: Miniaturized systems allow the integration of more mission-critical components, such as sensors, wireless communication devices, control units, and power generators, into smaller packages. This increases payload efficiency, reduces power losses, and enhances thermal management.

- Reliability & Flexibility: Integrating multiple microsystems into a silicon wafer and redundancy by design increases reliability and flexibility. Smaller, more reliable systems can reduce operating risks associated with space missions.

- Cost-effective Solutions: Terrestrial micro-technologies can offer superior performance compared with their in-space counterparts. These earth-bound solutions come with significantly lower development costs, more sustainable functionality, and stricter quality supervision.

It’s Just the Beginning:

The future holds many exciting possibilities that will require pushing the boundaries in the development of ever smaller and more complex miniaturized components and micro/nanotechnologies to support Aerospace and Space Robotics. We’re looking forward to highly functionalized new systems while updating existing capabilities in space, plus utilizing big data and quantum computing.

Back on earth, however, any and all technological breakthroughs require the cutting-edge know-how of design engineers and PCB manufacturers, with the advanced fabrication and IC packaging capabilities to bring the future of space exploration to life.

When you think miniaturization, think iNPACK (A PCB Technologies Company): Experts in organic substrates and enhanced micro-electronics packaging technologies. iNPACK capabilities enable us to deliver complete and comprehensive substrate panel-level manufacturing and engineering support to our customers across the board, in fact they depend on it. Contact our experts anytime to discuss your project needs.