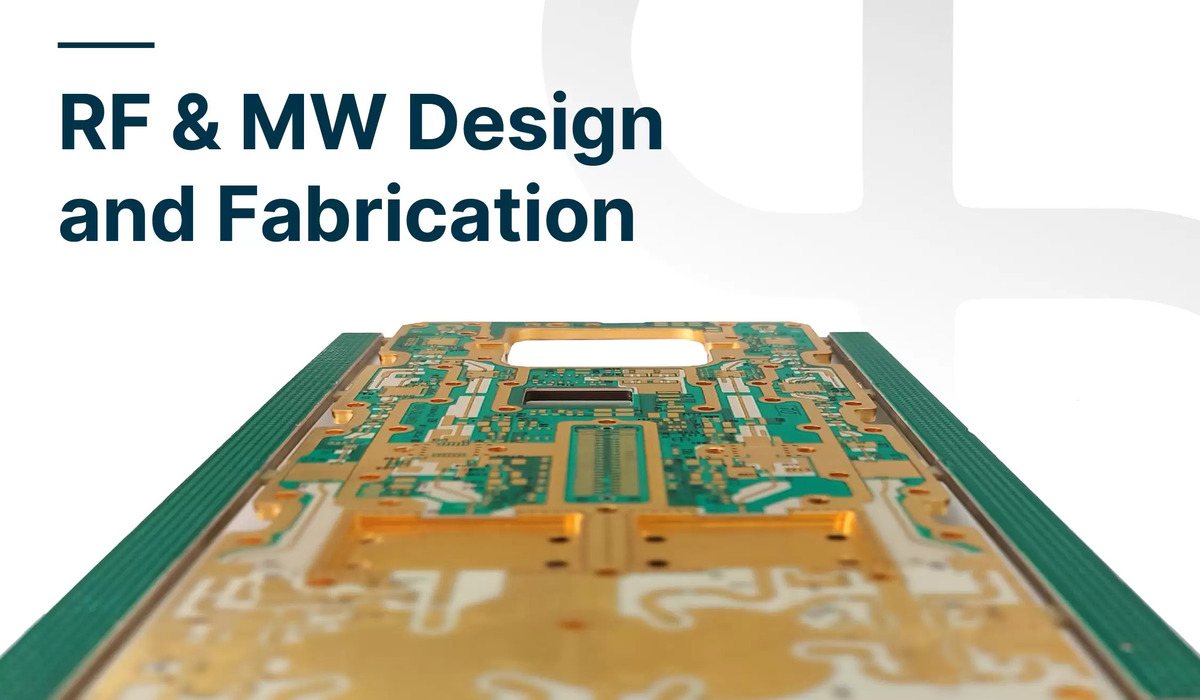

Flex Rigid PCBs: Why You Should Use Them

Yaad Eliya

|13th January ,2025

Introduction

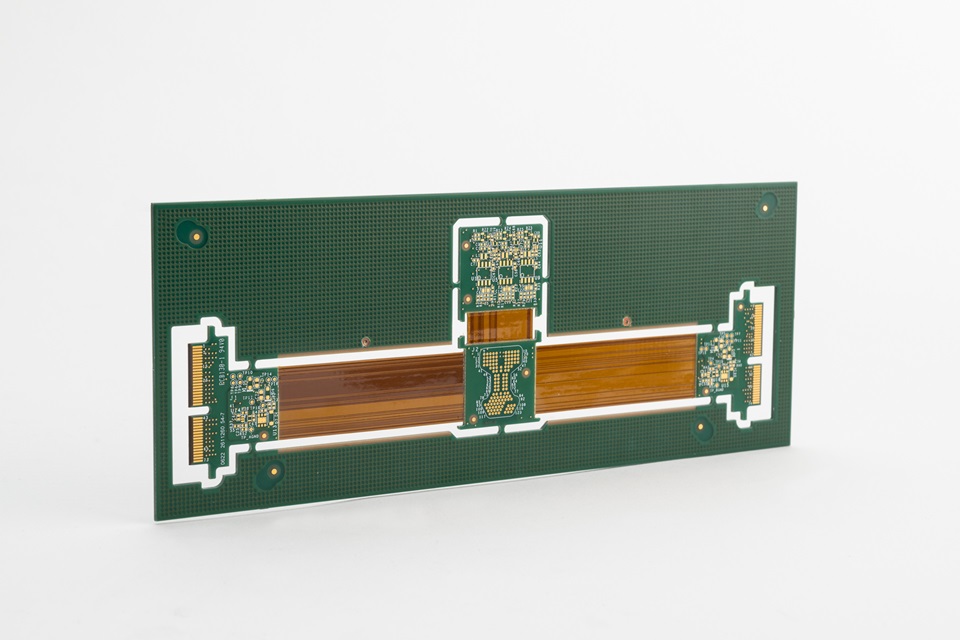

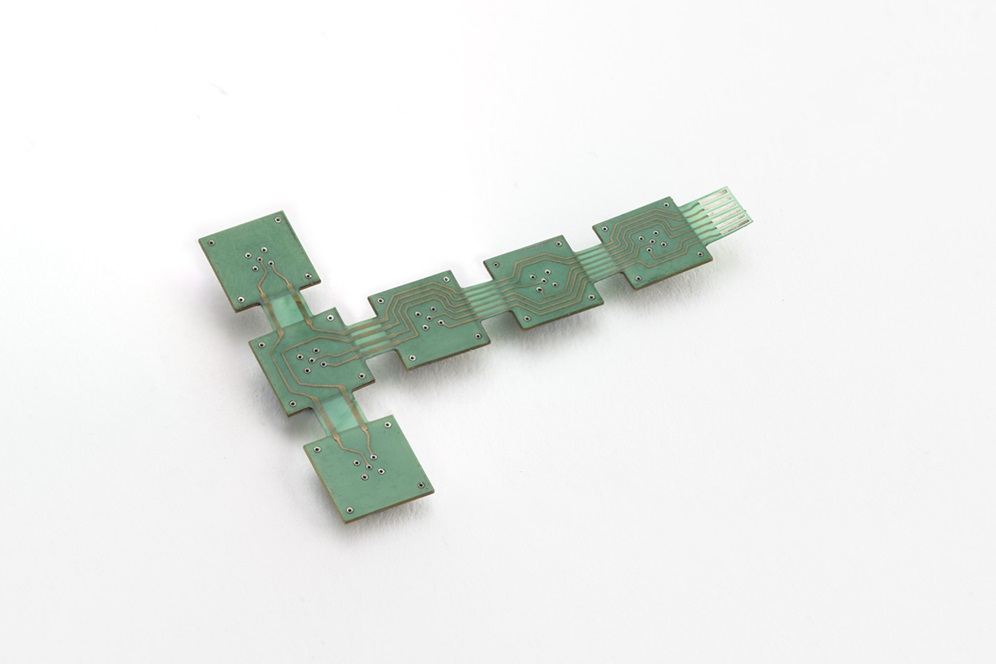

The flexible substrate functionality of Rigid-Flex or Flex Rigid PCBs offers greater spatial efficiency in achieving sub-compact packaging at a significantly reduced product weight. Designed in a 3D space, flexible board substrates can twist, fold, and roll into almost any desired shape and size to accommodate final package placement. The Rigid-Flex materials consist of polyimide on a Cu cladding substrate connected to an FR4 rigid board. Most Rigid-Flex boards feature multiple layers of flexible circuit substrates with via-hole interconnects and can be attached both externally or internally to one or more rigid boards. Driven by its unique advantages in size, weight, flexibility, and performance, market demand for Rigid-Flex PCBs is strong and growing.

What Are Rigid-Flex PCBs?

Rigid-Flex PCBs combine the best features of both rigid and flexible PCBs into a single unit, integrating rigid segments for structural stability with flexible layers that provide the versatility to accommodate complex geometries. Unlike traditional PCBs, which are confined to a two-dimensional layout , Rigid-Flex PCBs allow seamless electrical and mechanical connections in three-dimensional spaces. This hybrid design minimizes the need for multiple components, reduces weight, and enhances reliability by eliminating common failure points.

Key Advantages of Rigid-Flex PCBs

1. High Reliability

Rigid-Flex PCBs reduce the need for board-to-board connectors and solder joints, common failure points in traditional designs. This inherent reliability makes them ideal for critical applications where performance and durability are paramount.

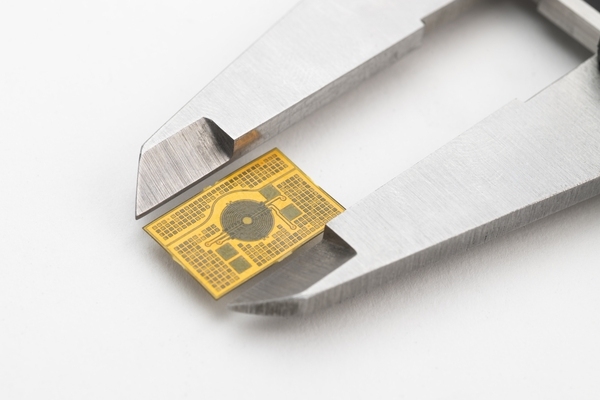

2. Miniaturization

The ability to bend, fold, and twist into compact spaces allows Rigid-Flex PCBs to replace multiple connectors and wire harnesses with a single integrated unit. This capability has revolutionized the design of portable and wearable electronics, including laptops, cameras, robotics, automotive systems, and medical devices.

3. Enabling Hybrid Structures

Implementing a hybrid structure, with RF/MW materials in outer layers and DC in inner layers, with FR4/POLYIMIDE at the core of the layer structure, enables miniaturization, reduces size and weight, and enhances electrical performance.

Rigid-flex layer structure, entirely suitable for RF, MW, with low dielectric constants of raw materials, DK= 3.5, 3.3, 3.0

4. Enhanced Testing and Integration

Since interconnections are tested at the PCB manufacturing level, Rigid-Flex PCBs simplify system integration and testing. Subcircuits can be connected seamlessly to the main design, enabling automated testing processes and reducing development timelines.

5. Cost Efficiency

By integrating flexible circuits with rigid boards, Rigid-Flex PCBs reduce the number of components and assembly steps required, lowering overall manufacturing costs. They provide the flexibility of a flex circuit at a cost closer to that of rigid PCBs.

6. Durability in Extreme Environments

Rigid-Flex PCBs are well-suited for challenging environments where mechanical stress, temperature fluctuations, or vibrations could compromise traditional PCBs. Their robust design ensures reliable operation in demanding conditions.

Flex Rigid PCB:

Unique Technical Features and Design Characteristics

-

- Layered Construction: Multiple flexible layers interconnected with vias can be incorporated into the rigid sections, enabling high-density interconnections.

- Material Synergy: Polyimide in flexible sections provides excellent heat resistance and dielectric strength, while FR4 in rigid sections ensures mechanical stability.

- 3D Design Capability: Enables complex geometries and efficient use of space, essential for modern compact devices.

- Thermal Management: Advanced thermal management options, including integration with low CTE substrates, ensure reliability under extreme operating conditions.

Applications Across Industries

The versatility of Rigid-Flex PCBs has driven their adoption across a wide range of industries:

-

- Consumer Electronics: Compact devices like smartphones, tablets, and wearables benefit from the space-saving and lightweight properties of Rigid-Flex PCBs.

- Wearable Devices: Sport devices such as fitness trackers, smartwatches leverage the flexibility and durability of Rigid-Flex PCBs to ensure reliability and comfort.

- Automotive: Essential for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle power management.

- Medical Devices: From implantable devices to diagnostic equipment, Rigid-Flex PCBs enable miniaturization and reliability in life-critical applications.

- Aerospace and Defense: Withstand extreme conditions while providing reliable performance for avionics, navigation systems, and military-grade equipment.

- Industrial Automation: Enable robust and compact designs for robotics, sensors, and control systems.

Flex Rigid PCB

Manufacturing Technology and Processes

The manufacturing of Rigid-Flex PCBs involves precise engineering and strict quality controls to ensure reliability and performance:

- Material Selection: Choosing the right combination of polyimide, copper cladding, and FR4 materials to meet specific design requirements.

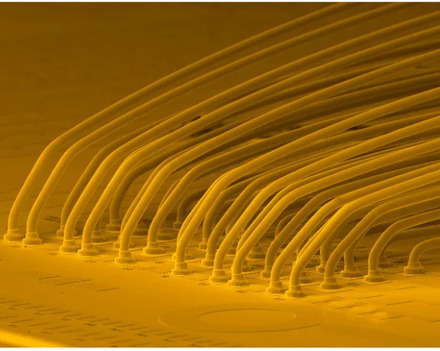

- Lamination: Flexible and rigid layers are laminated together, requiring careful alignment to avoid warping or misalignment.

- Drilling and Via Formation: Accurate drilling ensures reliable electrical connections between layers.

- Etching and Plating: The circuit patterns are etched, and vias are plated for electrical conductivity.

- Testing: Extensive electrical and mechanical testing is performed to validate functionality and durability.

Looking Ahead: Emerging Trends

The future of Rigid-Flex PCBs lies in their continued evolution to meet the demands of emerging technologies. Advancements in 3D IC packaging, miniaturization, and higher-density designs are driving innovation. Applications in IoT, 5G, and advanced medical diagnostics are expected to expand, further solidifying the role of Rigid-Flex PCBs in next-generation electronics.

Why Choose PCB Technologies?

PCB Technologies is a leading expert in advanced PCB solutions, specializing in Rigid-Flex, HDI, and RF PCB manufacturing. All materials and structures undergo rigorous testing in our internal reliability laboratory. When a design presents challenges related to reliability or manufacturability, we proactively identify potential issues and recommend optimal alternatives based on specific system requirements, including environmental conditions, vibration profiles, thermal cycling, and other critical parameters. PCB Technologies remains committed to helping you achieve your goals with precision and excellence.