When is a Miniaturized PCBA the Right Option for You?

Yaniv Maydar

|7th November ,2023

iNPACK™ ( a subsidiary of PCB Technologies ) is at the forefront of the miniaturized PCBA evolution, and we’d like you to join us there! This blog explores some of the major benefits, unique features, and diverse applications central to miniaturized PCBA design and can hopefully help you determine when it’s the right technology choice for your project needs.

Space, The Final Frontier:

When it comes to trendy electronics such as wearables, IoT devices, and portable apparatus, it’s all about space constraints, and saving space has become the holy grail of board designers. These constraints are driven mainly by market demand for reduced weight, portability, increased battery size, and aesthetics (sleeker device profiles). These expectations can only be met through miniaturizing the PCBA.

Devices On-The-Go:

‘Quality Attributes’, that is, design specifications that have little to do with actual device functionally, are becoming increasingly important. Portability is one such attribute. On-the-go items include wearables, drones, and portable medical equipment such as defibrillators. There is no question that these devices require compact, lightweight components that only a miniaturized PCBA can provide.

Wearable devices: smartwatches, fitness trackers, health monitors, and even connected clothing have their own set of quality attributes and space constraints. End-user standards for comfort and flexibility must be met, and because these devices come into skin contact with the wearer, thermal controls must be strictly regulated. New-age materials, along with miniaturized/optimized PCBA design, can address these concerns.

About Power Consumption:

There is a strong link between miniaturized PCBAs and improved overall energy efficiency. Typically, smaller PCBAs house fewer components, which allows for improved heat dissipation. They also feature shorter trace lengths and less space between individual components, resulting in decreased resistance and improved signal integrity.

By miniaturizing PCBAs in battery-powered devices, where every mW counts, designers can reduce the spread between the components and the power source. This, in turn, decreases power losses due to resistance and capacitance. Economizing on power consumption can significantly increase battery life, and that’s a big perk for users of every type of battery-operated device. So, thanks to miniaturized PCBAs, they can enjoy extended usage between charges.

Thermal Management:

Effective thermal management is critical in electronic devices, where excessive heat is the enemy, degrading performance and significantly cutting down component life. Coming to the aid of thermal management, the miniaturized PCBA design reduces the distance between heat-generating components and the board’s thermal vias or heat sinks.

This allows for more efficient heat dissipation and improved temperature regulation that prevents overheating to ensure reliable, steady device operation. It is of particular importance in applications such as LED lighting, where heat dissipation is a major concern, with adverse effects that directly impact product performance and longevity.

Signal Integrity & EMI:

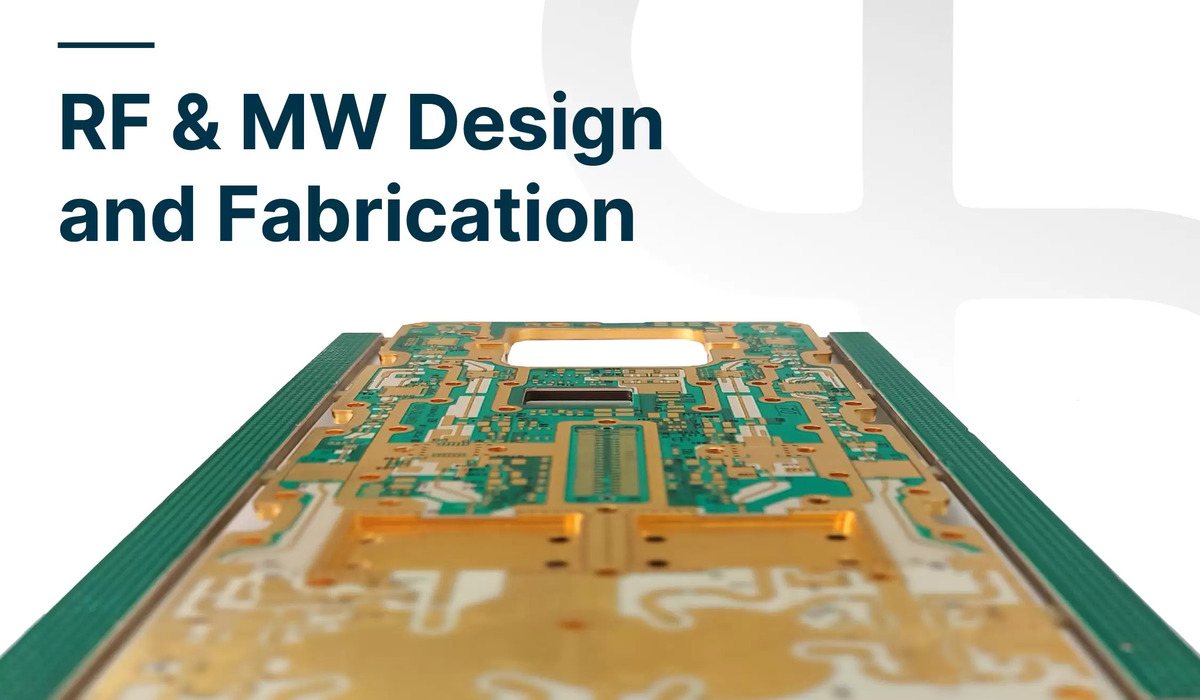

Miniaturizing the PCBA helps to mitigate signal degradation and electromagnetic interference (EMI). By reducing trace lengths and the proximity between components, the likelihood of signal loss or interference is significantly diminished. This is crucial for high-frequency applications or devices operating in high-noise environments, where maintaining signal integrity is of paramount importance.

It is also critical in applications such as high-speed data communication and RF systems, where even slight noise interference can cause signal degradation and data loss. By reducing the size of the PCBA, designers can minimize parasitic capacitance and inductance in the circuit, reducing noise and improving signal quality.

In Conclusion:

Having covered space optimization, power efficiency, thermal management, enhanced signal integrity, and more, we hope you’ve gained some valuable insights into when PCBA miniaturization is the right option for you. As always, striking a balance between functionality, design, and manufacturing costs enables engineers and designers to develop electronic devices that are perfectly aligned with their target markets.

When You Think Miniaturization, Think iNPACK™

We go beyond design limits to offer you organic substrates and advanced packaging solutions that help you to reach your targets. PCB Technologies are your partner in miniaturization, so don’t hesitate to contact one of our experts to find out how we can help meet your project needs.