Supporting Semiconductors machine manufacturers

VARDIT HARZMAN

|4th January ,2022

The semiconductor’s supply chain’s delays we have been accustomed to ever since the COVID19 era began and their effect on the lives of people all over the world are accelerating. The ever-growing demand for High-Density Interconnects, the main building block of electronic miniaturization technology, sets yet another challenge for PCBs designers and manufacturers. These PCBs are expected to have extended functionality as well as decreased weight and energy consumption.

All are basic requirements in the various applications they are designated for such as automotive, aerospace, and medical, among others. Semiconductors machine manufacturers, operating under tremendous stress to keep up with the ongoing global market demand for PCBs require not only high-speed operating machines but also highly accurate and reliable ones. PCB Technologies’ All-in-One approach, provides the technological breakthrough these manufacturers have been waiting for.

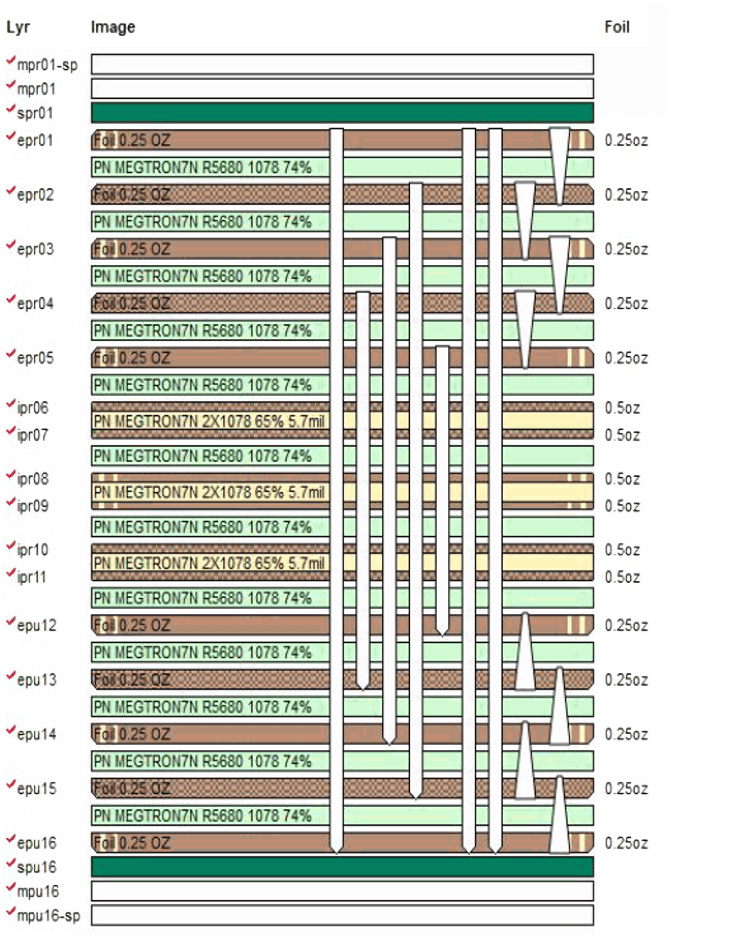

Two of our most unique assets have been utilized for that end. On the one hand – our vast experience in special raw materials helped identify the right one to be used. Megatron7, characterized by Ultra-low transmission loss and high heat resistance capacity, matched the need for high-speed large volume data transmissions, and at the same time constant high level of heat dissipation. This material is rarely influenced by heat/cold deviations or vibrations. The second asset is our capacity for combining mechanical and micro-vias.

This dual process contributed to the PCBs’ High density, and accuracy while forming multi-layered and large-sized PCBs. As shown in the stack-up below we have managed to laser-drill up to 4+N+4 vias assuring a high level of sequenced electrical conductivity and operability. In the end, it all comes to profitability, and in a world where time is money, any means of saving time inevitably save money. A lot of it.