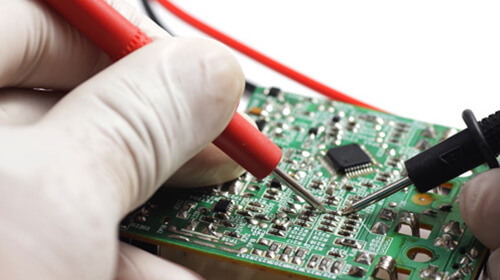

High-reliability, high-performance communication PCBs ensuring signal integrity

PCB Technologies’ design and fabrication capabilities are just what customers in search of cost efficient electronic communication devices manufacturing are looking for. The latest trend of 5G and 6G technologies affect applications, such as mobile products, portable consumers, servers, data centers, antennas, communication centers transmitters, receivers, etc., for a variety of industries, such as aviation, consumers, automotive, and medical. We provide large format panels maximizing the utilization of high aspect ratio plating.

We specialize in RF and Microwave based PCBs, essential for supporting these types of products. We supply high reliability, high-performance communication PCBs ensuring signal integrity throughout the product’s lifecycle, without any transmission delay or latency. We provide solutions for impedance issues and use various blind, buried, or micro via structures as a means for device miniaturization requirements. When relevant to the device at hand we can also offer HDI, Rigid, Flex, and Rigid-Flex fabrication solutions. We follow the strictest quality standards and conduct numerous automated tests and inspection procedures to ensure we supply the best products possible.